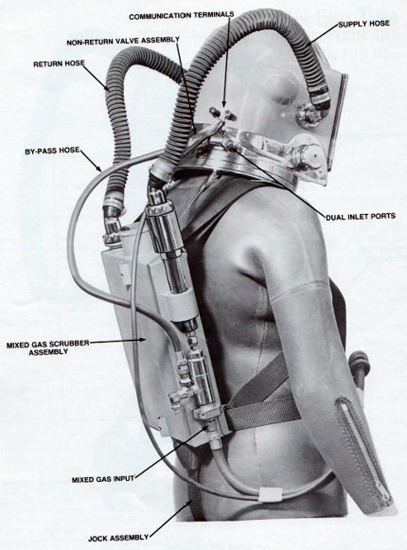

The mixed gas diving system uses a helium-oxygen mixture and when used with the back pack scrubber pack means a significant reduction in the amount of gas required. The helmet's development meant the diver had great versatility and could wear fins for free swimming or weighted boots for bottom work . A variety of suits was also available including dry suits wet suits or even hot water suits. The helmets were distributed through Diver's Echange, INC in the USA and through Divex (UK) LTD in England.

George Swindell the inventor of

the Advanced Diving Systems Helmet seen here demonstrating an early helmet

without the

breastplate. You can clearly see the jock strap system assembly which is

used to hold the helmet firmly on the diver's head.

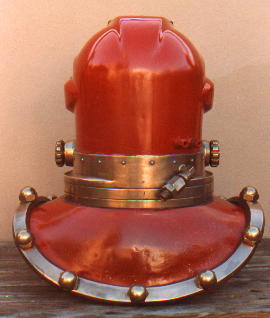

Model 2000 helmet with optional breastplate

Model 3610 Mixed gas system